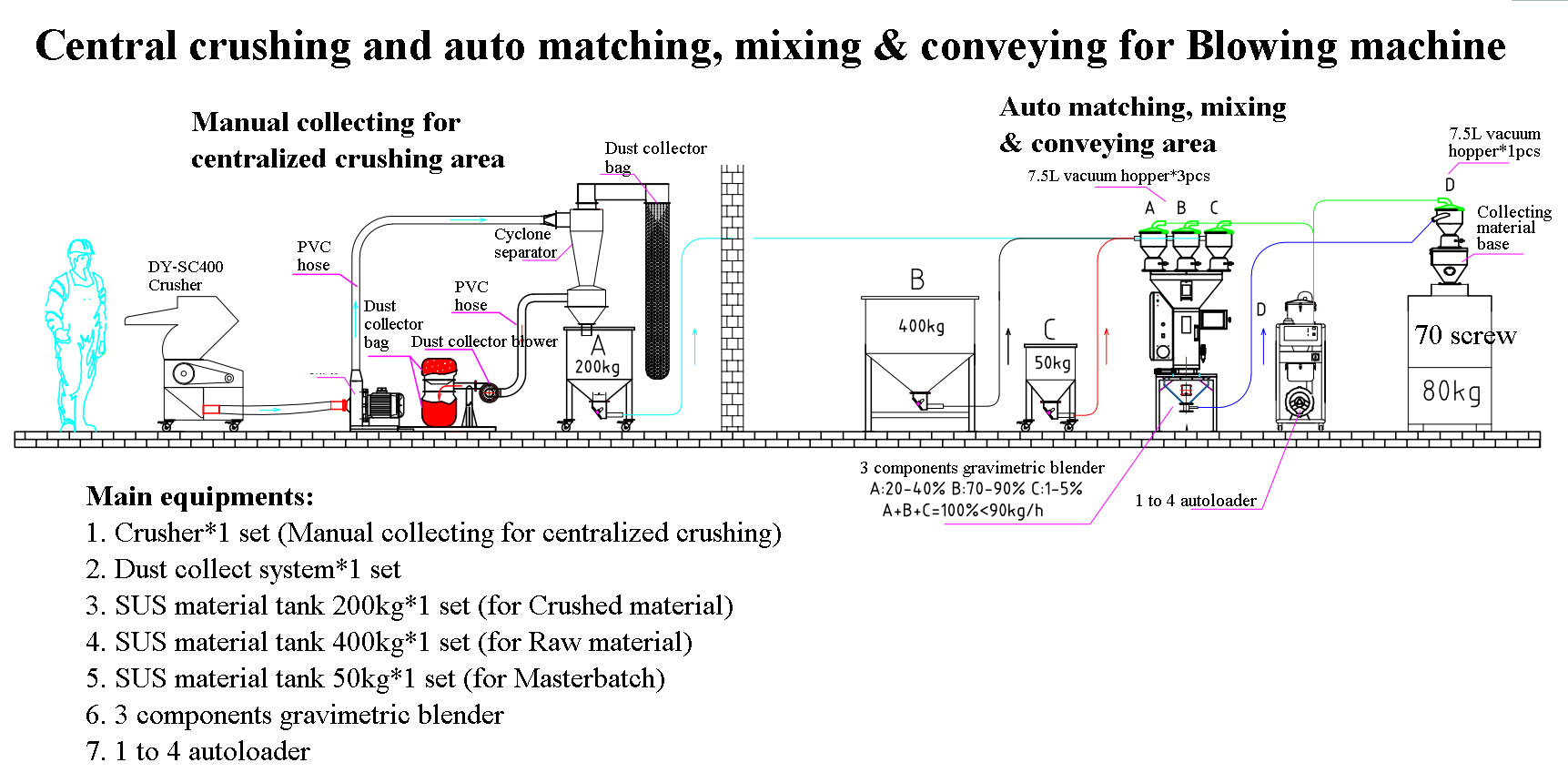

The blow moulding process consists of two main moulding methods: extrusion blow moulding and injection blow moulding. Through extrusion or injection moulding, thermoplastic resin is moulded into the tube-shaped parison, which is instantly (when it is still hot or heat it to the state of softening) put into a blowing mould. Then compressed air is blown into it until it expands and sticks to mould cavity. After cooling and demolding, the hollow product is ready. At Dingyuan, we offer various material handling equipment prior to the production process that best meets your production needs. Dingyuan provide one stop solution for Extrusion Blow Moulding System: Central crushing and recycling, auto matching, mixing, conveying and cooling, etc.